Loader solution

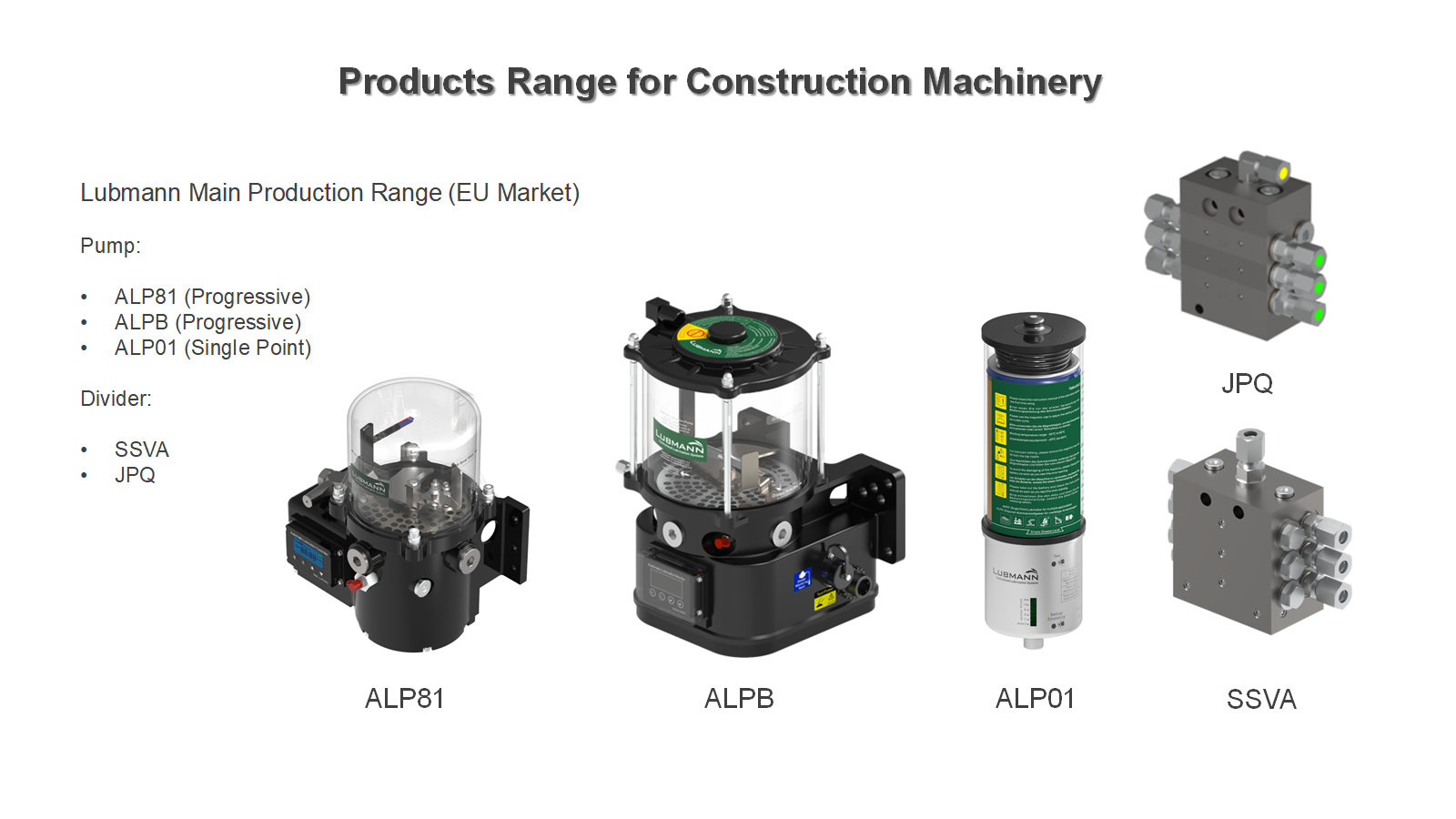

For loader lubrication solution, Lubmann provide progressive or dual line lubrication system.

Both of the systems supply quantitative grease automatically, reducing maintenance costs and frequency of maintenance operations.

Main Components

For various loader, such as wheel loader, crawler loader, bucket loader, mini-size loader.

One system is main composed of grease pump, distributor, monitor, pressure sensor, tubes and fittings.

Excavator solution

A progressive or dual line centralized lubrication system is used for the lubrication of an excavator. If there is something wrong, the grease pressure sensor at the end of the distributor which monitors the system in real time will send fault signal and stop alarm. The lube supply for each lube point can be set according to the real need.

For dual line system, the fault of one lube point will not cause affects on other lube points because they are connected in parallel, which is a redundancy design.

Main Components

For various excavators like wheel type or track type, one system is main composed of grease pump, distributor, monitor, pressure sensor, tubes and fittings.