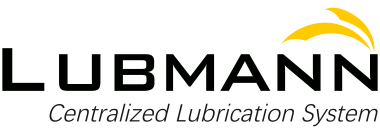

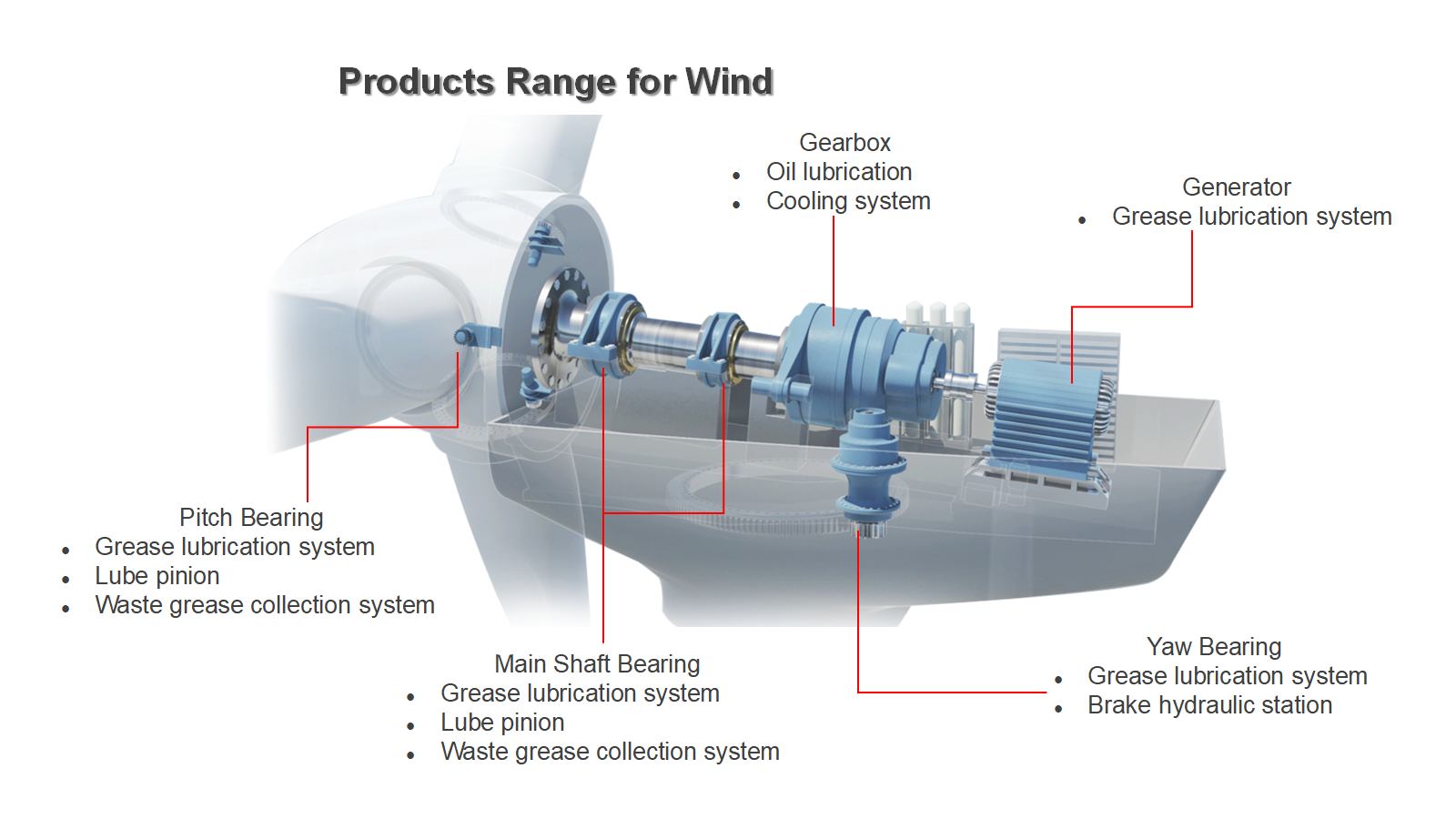

Wind Turbine automatic lubrication solution

- Reduce labor intensity of maintenance staff and decrease maintenance loss

- Reduced friction and wear, improve the service life of the bearings and gears

- Reasonable & automatically control grease volume of bearing to ensure lubrication of the bearings are in good condition, make sure the bearings and gears are working properly in harsh environments.

- Can lubricate some points which is difficult for manual lubrication.

- Reduced downtime cycle due to improper lubrication, making more safe and stable operation of wind turbine generator.

- Reasonable lubrication can reduce the waste of grease and pollution.

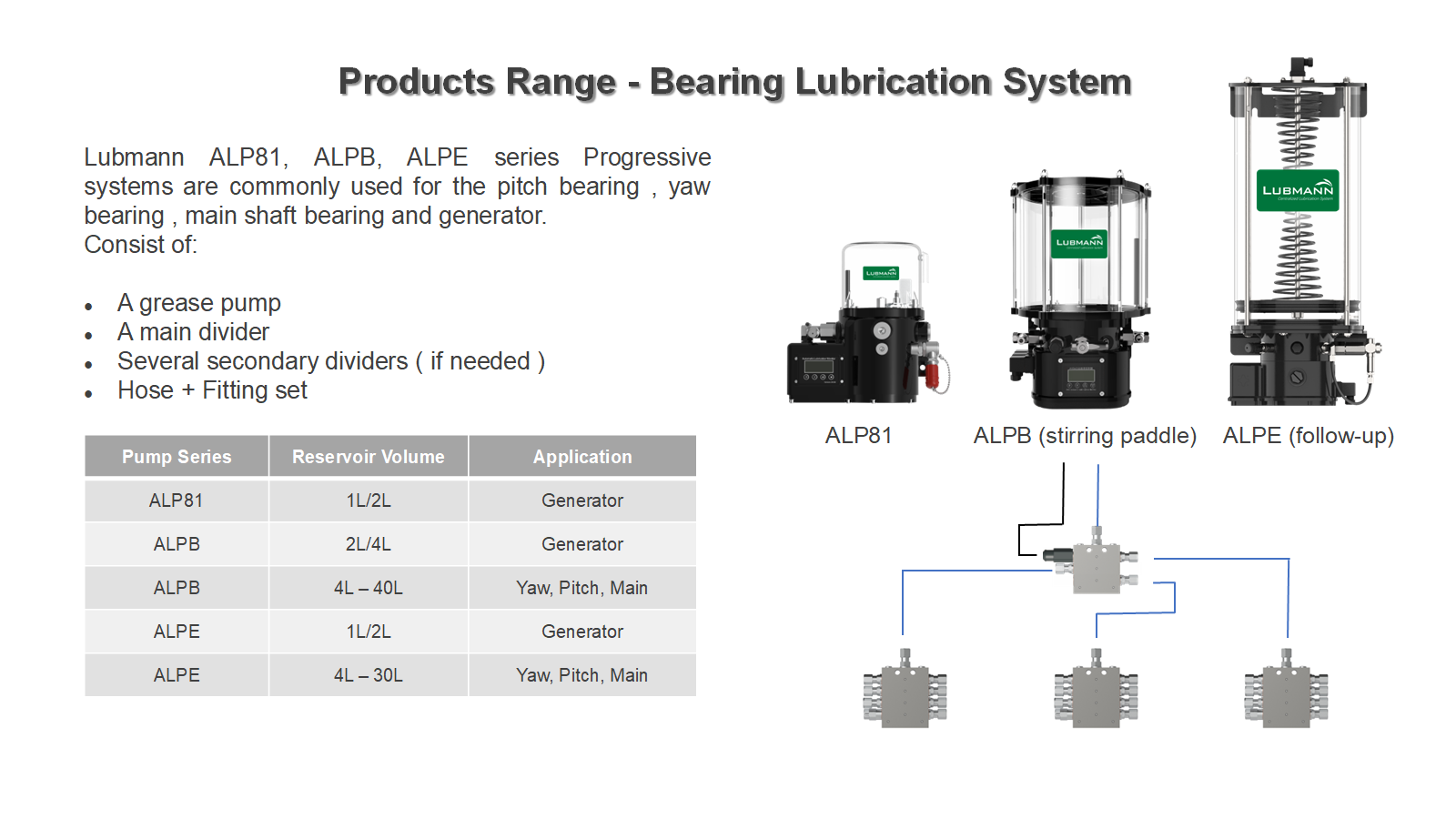

Wind Turbine waste grease collection system

- Remove the waste grease containing wear debris from the bearing chamber to reduce bearing friction, good to bearing heat dissipation and reducing bearing wear.

- The pressure in the bearing inner chamber is eliminated to ensure that the inner chamber is unclogged and make sure that new grease is filled into the bearing.