Advantages of Automatic Lubrication Solution for Commercial Vehicle Application

- Automatic system guarantees timing and automatic lubrication, which saves labor (95%) and ensures operators’ safety

- Longer vehicle life, expand its lifespan for more than 60%

- Save grease for more than 70%, environmentally sustainable

Introduction of the System

Lubmann innovated new centralized lubrication system for commercial vehicles and have maintained a long-term cooperation with varied coach and bus manufacturers. Here are the common lubrication series for coach and bus:

LFS Series: LFS-1, LFS-2, LFS-3

Technology innovation:

- The country-around and year-around application of highly dense 0# lube

- ECU smart controlling system

- New pressure-type distributor with high pressure, stable performance and good lubrication

- Intelligent temperature control system solves the application problem of the system in high cold region

Main Components:

Grease Pump (LFS Serie)

The LFS Series lubrication pump can be used as a centralized lubrication pump in pressurized single line systems. It can drive 1 element. The pump’s drive and eccentric shaft design, high-efficiency worm gear, minimal number of parts and multi-range motor provide several advantages.

LFS Series pumps are available with a three-phase flange mount and multi-range motor or with a free shaft end for use with other motors Various gear ratios and reservoir sizes with or without level control are offered.

Pressure Distributor

At normal temperature, the maximum discharge pressure may be up to 3.2 MPa. Under low-temperature environment, the discharge pressure will be increased with reduced ambient temperature.

Max. pressure: 8.0 MPa. Displacement: 0.1 ml, 0.2 ml, 0.4 ml/cy. Grease available: NLGI—00#, 0#, 1#

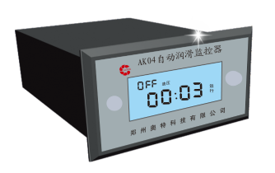

Monitor

As a control center of the lubrication system, the monitor is used to dynamically display the grease pressure in the grease line, time countdown to the OFF state, operating hours, total number of operations and fault code, etc. and, it features protection for standby at low temperature and fault alarm.

The monitor may be built-in or externally mounted. A built-in monitor is integrated with grease pump and with reserved position. An externally mounted monitor is installed for easy operation.